Compressed Air Energy Audit

Let us at Design Air help you identify significant cost and energy savings on your electrical costs each year by carrying out a comprehensive air energy audit for you. A professional air energy audit is one of the most effective ways to reduce energy consumption, lower operational costs, and improve the overall system efficiency of your plant.

Air Energy Audits: Why Have a Compressed Air Energy Audit Carried Out?

Problem: The Hidden Cost of Your "Fourth Utility"

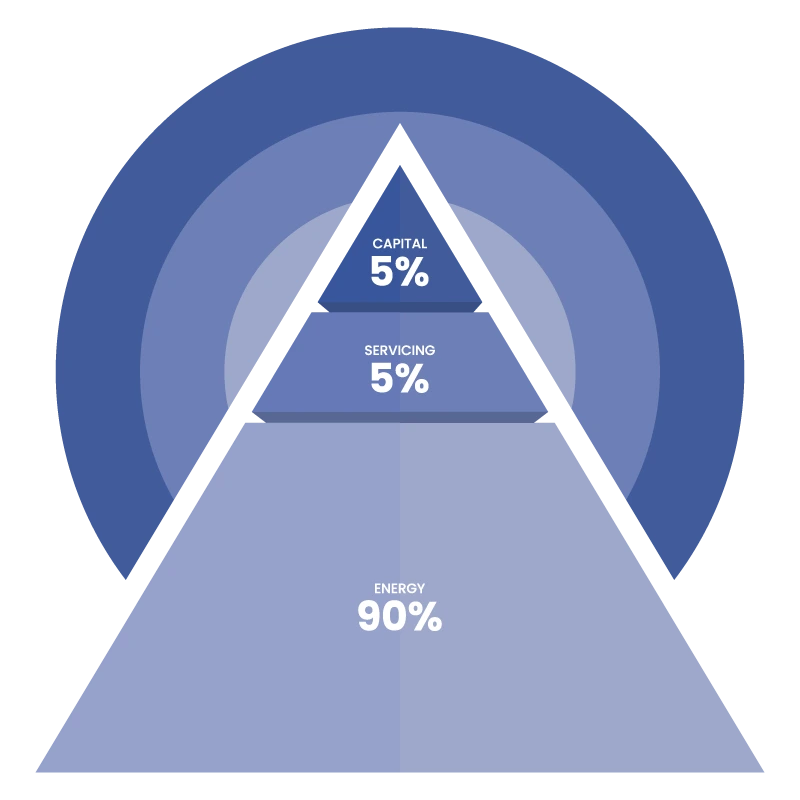

The majority of cost associated with owning and operating a compressed air system is the energy consumption associated with running the equipment. Over a typical 10 year lifecycle 90% of the cost is associated with running the equipment, and only 10% is buying and servicing. For many UK industrial facilities, running air compressors can account for 10-15% of the total electricity bill, yet systemic inefficiencies mean much of this energy is wasted.

Saving Opportunity: Unlock Potential Cost Savings

The biggest opportunity to achieve cost savings is to increase the system efficiency of your compressed air system, thus reducing your energy usage and improving system performance. Reducing your maintenance scope and purchasing cheaper, less efficient air equipment will typically cost you more over the lifespan of the equipment. Our audit provides a clear roadmap to potential energy savings.

Solution: A Data-Driven Approach

Have Design Air carry out a compressed air energy audit for you to identify solutions that could save you significantly on your annual electrical costs. Often these solutions will not cost you anything to implement thus giving you an immediate return on investment!

What's Involved? Our Compressed Air Energy Audit Checklist & Procedure

1. Initial Interview & Goal Setting

Initially we would conduct a brief interview with you to determine what goals you would like to achieve by having the audit carried out as well as identifying key personnel and resources involved in the process.

2. Site Survey & System Mapping

This is likely the longest part of the process but the most critical to help achieve your desired goals. At this stage, our audit team would record details of equipment and survey the entire compressed air system including;

- Compressed air generation (rotary screw compressors, receivers, air dryers, filters and condensate treatment)

- Compressed air distribution system (pipework ringmains, headers, and drops)

- Compressed air usage points (application, system pressure, consumption if known)

3. Data Logging & Testing

We will install a data logger in each compressor room. Every second this will measure your compressor system's Power consumption, Pressure and estimated Flow, logging the results over the course of a week. This method of monitoring compressed air helps us understand your true compressed air demand. We can also where required install / log the air flow results from flow meters in order to measure actual flow vs. having this estimated.

4. Air Leak Detection

Whilst the data logging is being carried out, we would recommend a complete ultrasonic air leak detection survey for you. This will help to identify the majority of compressed air leaks within your pneumatic system to help fully assess areas of wasted energy costs. A simple leak can cost thousands per year. Why invest in an oversized compressor size / dryers when reducing your air leakage rate could result in a requirement for smaller and cheaper to run equipment?

5. Analysis and Assessment

Once we have received the data from our loggers and leak detection, we will graph the results and spend time at our offices performing an analysis of the results. This analysis will be performed by an engineer who holds a diploma in Compressed Air Management (dipCAM) to ensure that you receive the best possible advice. We check all system dynamics to identify areas of improvement.

6. Detailed PDF Report Production and Proposals

Following the analysis, we will produce a full compressed air energy audit pdf report on your Compressed Air System's operation and electrical energy efficiency. You will be provided with a grade depending on how close your system is to the most electrically efficient system you could be running. Depending on what goals you set at our initial meeting, we will issue you with an improvement plan and proposals to help reduce your annual electrical energy costs. Each proposal for improvement will come with an estimated annual electrical energy cost saving and thus return on investment calculation.

Common Problems We Identify

Our air audits often uncover significant inefficiencies. These are the most common sources where energy is wasted:

- Air Leaks: Often the biggest culprit, compressed air leaks can account for 20-30% of your compressor’s output. We use ultrasonic air leak detection to find and quantify them.

- Artificial Demand & Over-pressurization: Running your system pressure higher than needed is incredibly costly. For every 2 psi (0.14 bar) increase, energy efficiency drops and energy consumption rises by ~1%. We identify the lowest acceptable pressure for your applications.

- System Misuse: Using high-cost compressed air for applications like cleaning or cooling when a low-pressure blower would be far cheaper. We identify these and suggest more efficient alternatives.

- Poor System Design & Pressure Drop: Undersized pipework, clogged filters, or excessive bends create pressure drop, forcing your air compressor to work harder. This reduces system performance and efficiency.

Key Benefits of Our Compressed Air Audit Services

A professional audit is the first step toward a robust energy management plan. The benefits go far beyond just saving energy:

- Achieve Significant Cost Savings: We provide a clear ROI for each recommendation, showing you how to reduce energy and save money.

- Improve System Reliability: By identifying stressors, we help extend the life of your compressed air equipment and prevent costly, unplanned downtime.

- Optimise Air Quality: We can assess your dryers and filtration to ensure your system is meeting the specific air quality requirements for your applications.

- Support UK Compliance: An audit provides the data needed for your Energy Savings Opportunity Scheme (ESOS) reporting and supports your ISO 50001 energy management goals. We also help review safety in line with PSSR 2000.

Frequently Asked Questions

A compressed air audit (sometimes called an AIRScan) is a comprehensive assessment of your entire compressed air system. It measures your current energy use, air demand, and system efficiency to find opportunities for reducing energy consumption and saving money.

You need an audit if you are facing high electricity bills, experiencing pressure drops, or unsure if your compressor system is sized correctly. It’s the most effective way to identify and eliminate energy waste, with many businesses saving 20-50% on their compressed air energy costs.

The compressed air energy audit cost varies depending on the size of your facility and the depth of analysis required (e.g., simple walkthrough vs. full data logging). However, many businesses find that the audit pays for itself quickly through the identified energy savings, often within months.

Generally, there are three levels: 1) A Walk-through Audit (visual inspection to find obvious waste), 2) An Assessment Audit (using data logging to measure system performance over time), and 3) A Full System Audit (a deep-dive analysis including leak detection, demand-side assessment, and comprehensive equipment testing).

ISO 11011 is the international standard for conducting compressed air energy efficiency assessments. Our audits follow this best-practice framework to ensure a consistent, high-quality, and comprehensive analysis of your system.

You will receive a detailed report that includes a baseline of your current energy use, a full analysis of your system dynamics, a quantified list of all identified air leaks, and a set of prioritised recommendations with clear costs and payback periods.