Remote Monitoring for Your Air Compressor System

Historically, responsibility for checking your compressed air system is operating effectively and efficiently would fall at the feet of your preventative maintenance team.

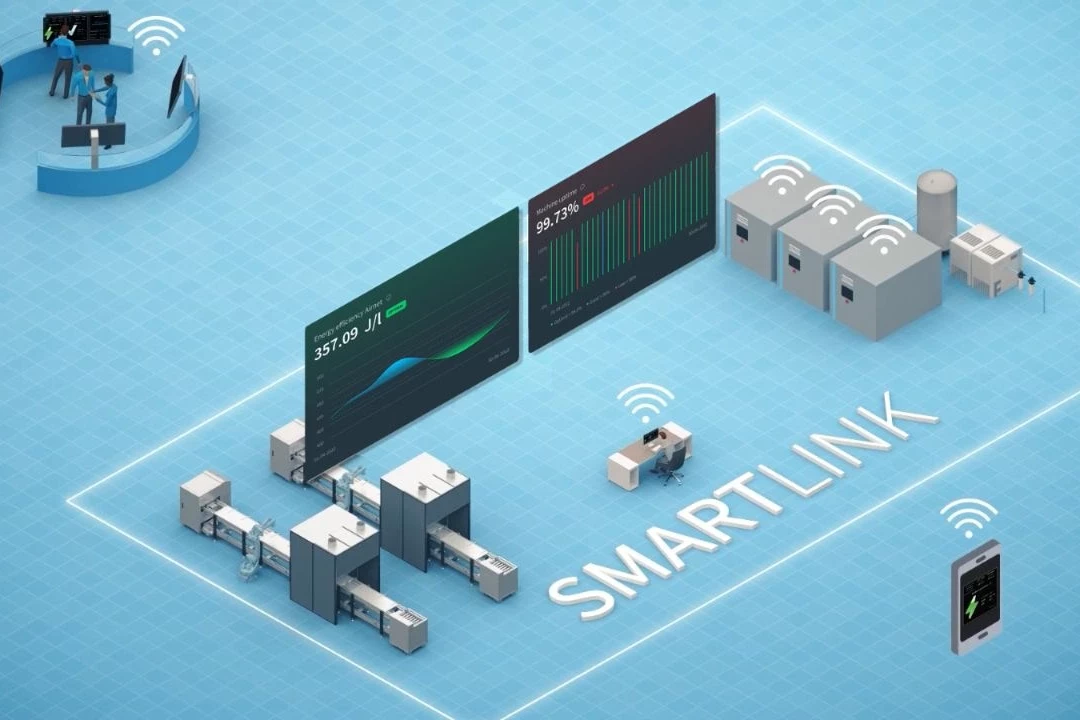

At Design Air, we can take this burden off of your team by implementing a robust air compressor monitoring system that provides monitoring for key system parameters for you anywhere, at any time! We do this through Atlas Copco SMARTLINK. This gives us real-time access to all vital operating parameters and compressor data. As such we can help increase your energy efficiency and reliability by highlighting problems before they can cause any system downtime, shifting your maintenance from reactive to proactive.

Benefits of Remote Monitoring

Prevent Lost Production with Proactive, Predictive Maintenance

If you opt for SMARTLink Uptime, we will constantly monitor key operating parameters of your compressed air equipment. This real-time monitoring allows us to forecast potential issues and breakdowns. This is the core of predictive maintenance: using live and historical compressor data to ensure system health. As such, we can advise you of potential problems and act upon them before it gets to this point. You’ll receive an instant notification or alert if parameters fall out of range, allowing for early detection of faults.

Accurate Service Scheduling for Peak Performance

With SMARTLink Service we will be able to accurately determine the exact time when the equipment will require its next service. This ensures that the equipment will be well maintained in accordance with manufacturers guidelines and also ensures that we are not over or under servicing the equipment at all, thus increasing system efficiency and keeping your maintenance costs to a minimum. This data-driven approach keeps your compressor performance at its peak.

Enhance Energy Efficiency & Compliance with ISO 50001

By opting for SMARTLINK Energy, you will receive customised reports on the energy efficiency of your compressed air equipment. This will help your organisation comply with ISO 50001 requirements and will help to ensure that your system is running in an efficient manner. These reports identify your energy consumption patterns, highlight potential energy savings, and can even spot costly issues like pressure drops or air flow inefficiencies, helping you achieve optimal efficiency and significant cost savings.

How Does Air Compressor Remote Monitoring Work?

A remote monitoring system transforms your compressor room into a set of data points you can access from anywhere. The process is simple:

1. Data Collection:

We install industrial-grade sensors on your air compressor and throughout your system. These sensors track critical data points 24/7.

2. Secure Transmission:

This compressor data is securely transmitted, often via a cellular network or your local area network (LAN), to a secure cloud-based system.

3. Analysis & Alerts:

The system analyses this real-time data. If it detects an anomaly (like a sudden temperature rise, pressure drop, or unusual vibration), it sends an immediate alert or notification to our team and yours.

4. Reporting & Access:

You can log in to a secure web dashboard or mobile app at any time to check in on your compressor, view performance dashboards, and track your system's health, giving you complete peace of mind.

Atlas Copco’s SMARTLINK is a world-class example of this technology in action, providing a robust, cloud-based system for monitoring your air compressor.

What Key Data Can We Monitor?

A modern air monitoring system tracks far more than just on/off status. We monitor a wide range of parameters to get a complete picture of your system health, including:

- Pressure: Using pressure sensors, we can track discharge pressure and system pressure to identify leaks, blockages, or pressure drops that waste energy.

- Temperature: Monitoring oil and element temperatures can predict overheating and prevent damage to critical components like the airend on rotary screw air compressors.

- Power Consumption (kW): Provides a direct, real-time look at your energy consumption, allowing us to calculate your Specific Power (kW/100 cfm) and identify inefficiencies.

- Vibration: Advanced vibration analysis acts as an early detection tool for bearing wear or misalignment, preventing catastrophic failures.

- Air Flow (CFM): Measures the actual air delivery of your compressor system, ensuring it matches your production demand without waste.

- Dew Point: This is critical for monitoring your air quality and dryer performance. A rising dew point indicates moisture is entering your system, which can damage equipment and contaminate products.

Frequently Asked Questions

While we are a Premier Atlas Copco Distributor, our remote monitoring system is brand-agnostic. We can retrofit our monitoring solution onto any brand of compressor, allowing you to monitor your entire compressed air system, regardless of make or model, from a single, unified dashboard.

Absolutely. This is a key benefit of our system. We can retrofit older, “legacy” equipment by installing modern sensors and an IoT gateway. This brings your existing assets into the digital age, allowing you to gain the benefits of real-time data and predictive maintenance without investing in a brand new compressor system.

We understand that operational data is highly sensitive. The systems we use are built with robust security at their core. Data is transmitted using end-to-end encryption, and the platform itself is often isolated from your internal IT network by using a secure, independent cellular connection. Platforms like Atlas Copco’s SMARTLINK are certified to high international security standards (like ISO 27001) to ensure your data is protected, giving you total peace of mind.