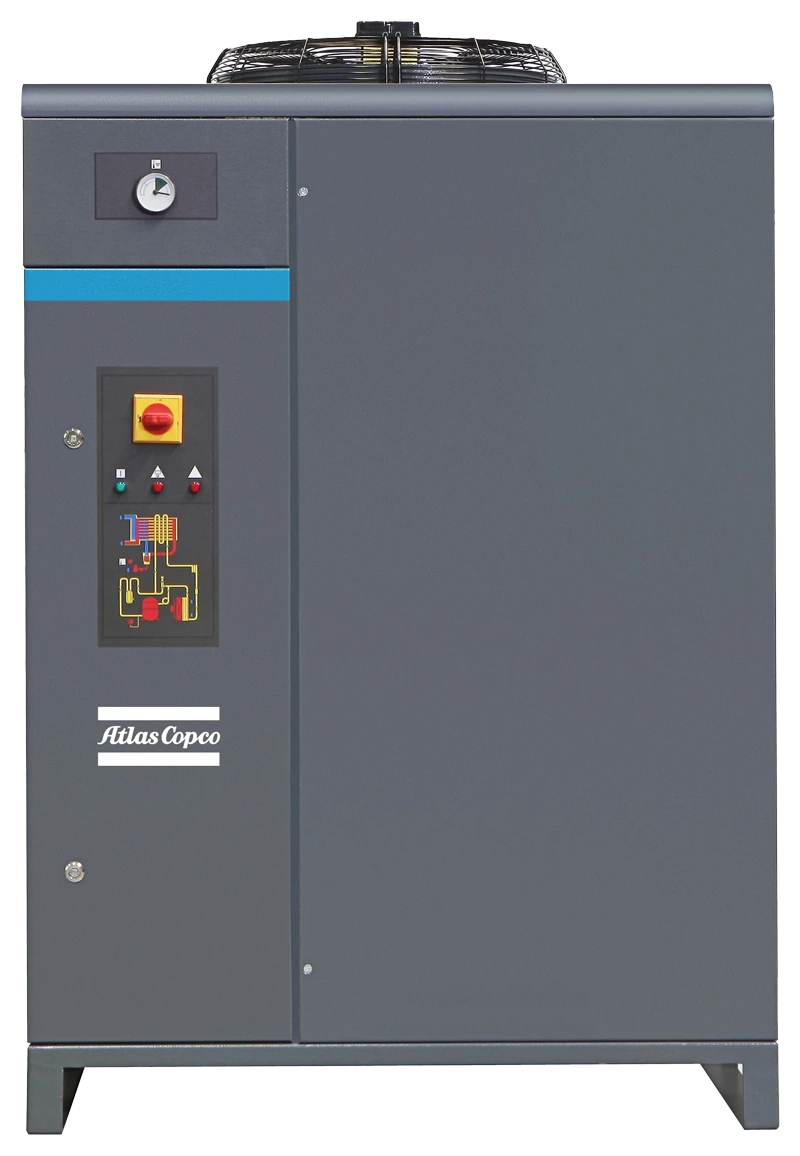

Atlas Copco Refrigerant Dryers

Moisture in your airline can often cause many problems for an air compressed air system. For example, this can cause rust and corrosion in a receiver tank, blocking the drain and causing the receiver to fill with water and condensate. It can also lead to excessive tool wear and tear, damage to pneumatic equipment, or spoil spray finishes in painting applications.

The solution is an Atlas Copco Refrigerant Dryer, a cost-effective and reliable air dryer designed to remove the majority of water vapour and avoid condensation from the compressed air supply. This process achieves a stable Pressure Dew Point (p.d.p) of down to +3°C.

How Does a Refrigerant Air Dryer Work?

A refrigerant dryer works on a simple, proven principle, much like a household refrigerator. This process provides clean, dry air in three steps:

- Chilling: Hot, wet compressed air from your compressor first passes through an air-to-air heat exchanger, which pre-cools it. From there, it enters an air-to-refrigerant heat exchanger where the refrigerant compressed air is rapidly chilled, forcing the water vapour inside it to condense into a liquid.

- Separation: This liquid moisture is then removed from the air stream by an integrated water separator and automatically evacuated by a drain.

- Re-heating: The now cold, dry air travels back through the air-to-air heat exchanger, where it is reheated before exiting the dryer. This prevents any ‘sweating’ or condensation from forming on your downstream pipework.

Understanding Pressure Dew Point (PDP) and Air Quality

The Pressure Dew Point (PDP) is the temperature at which compressed air is 100% saturated with moisture and condensation will begin to form. A refrigerant dryer that delivers a PDP of +3°C, like the Atlas Copco FX and FD range, guarantees that no liquid water will form in your system as long as the ambient temperature remains above 3°C. This level of dry air meets the ISO 8573-1:2010 Class 4 standard for air quality, which is ideal for the vast majority of industrial and manufacturing processes.

Why Choose an Atlas Copco Refrigerant Dryer From Design Air?

Lowest Total Cost of Ownership

As you will likely keep your new air dryer for at least 10 years, around 80% of your total cost of ownership in this period will be in electrical energy costs.

Atlas Copco Refrigerant Dryers are extremely efficient and are designed to minimise energy consumption, typically offering the lowest total cost of ownership when factoring in initial purchase price, electrical running costs and maintenance costs. This focus on energy efficiency helps cut energy costs and provides a rapid return on investment.

Financing Options

At Design Air, we can be flexible to meet your payment requirements. We appreciate that purchasing an Atlas Copco Dryer is a long term investment, so we can help you finance your purchase over 3-60 months

Instead of waiting for a return on your investment, make a saving immediately. We can demonstrate that your monthly payments will be lower than the electrical cost savings your new dryer will provide

7 Year Guardian Warranty

As official Atlas Copco Distributors, if you agree to a Guardian Service Plan with us, your new Refrigerant Dryer will come complete with a 7 year warranty.

We’re confident that our Guardian Service Plan will ensure that your new Refrigerant Dryer continues to run reliably and efficiently. However, in the event it doesn’t you wont pay a penny for the repair

Our Range of Atlas Copco Refrigerant Dryers

The Atlas Copco FX Series (Standard Dryers)

- Max Capacity: 14 - 2,374 cfm

- Max Pressure: 13 - 16 bar(g)

- Pressure Dewpoint: +3 DegC

The Atlas Copco FD, FD (VSD)+ Series (Premium Efficiency Dryers)

- Max Capacity: 13 - 8,480 cfm

- Max Pressure: 13 - 16 bar(g)

- Pressure Dewpoint: +3 Deg

Air Compressor FAQs?

A refrigerant air dryer, like the FX and FD models, cools the air to +3°C to remove moisture. This is the most common and cost-effective solution for most industrial applications. A desiccant air dryer uses adsorption material to remove water vapour to a much lower pressure dew point, typically -20°C, -40°C, or even -70°C. Desiccant dryers are only necessary for highly sensitive applications (e.g., food, pharma, electronics) or for pipework that is exposed to sub-zero, freezing temperatures.

The F-Gas Regulation is a UK and EU law designed to phase down the use of refrigerants with a high Global Warming Potential (GWP). All modern Atlas Copco refrigerant dryers are designed to be fully compliant with these regulations, using newer, low-GWP refrigerants like R410A, R134a, or R513A. As a certified F-Gas handling company, Design Air is legally qualified to install, service, and maintain your refrigerant compressed air dryer in full compliance with UK law.

Refrigerant dryers are designed to be highly reliable, but they require simple, regular maintenance to ensure they keep your compressed air system in optimal shape. The most important tasks, which are part of our Guardian Service Plan, include:

- Weekly: Checking the condensate drain to ensure it is discharging water and not blocked.

- Monthly: Cleaning the condenser fins to ensure unrestricted airflow and efficient cooling.

- Annually: Replacing the pre-filter element to protect the dryer’s heat exchangers from oil and dust.