Compressed Air Leak Detection & Repair

Compressed air leaks can account for up to 30% of your total industrial compressed air production if not managed correctly. In unmaintained systems, this leakage rate can climb to 50% or higher. As such, you could be wasting significant electrical energy costs on supplying compressed air to these leaks. This direct energy waste silently increases your maintenance costs, places unnecessary wear on your compressor, and can lead to production downtime.

Let us at Design Air help you detect leaks and repair them with our comprehensive leak detection & repair program. We provide professional industrial air leak detection solutions across Scotland, including key service areas like Glasgow, Edinburgh, Stirling, and Dundee.

Our promise is to save you enough energy costs to provide a return on investment of less than 1 Year

What's Involved With Compressed Air Our Leak Detection Program?

Step 1: Leak Survey & Inspection

The first step in the process is to conduct a thorough inspection and leak survey of your entire compressed air system with an advanced ultrasonic leak detector. This sensitive detection equipment finds the precise location of leaks by identifying the high-frequency acoustic signature they produce, a sound that is impossible to hear over the noise of a normal production facility. This will help to identify and pinpoint air leaks in your system, even in hard-to-reach areas.

Step 2: Tag & Quantify The Leaks

Once we have located the leaks, we physically tag each one with a unique ID. We then use our ultrasonic detection equipment to prioritise them in order of severity by estimating the leak rate (CFM). Large, easy-to-fix leaks will be given highest priority whilst small, hard-to-fix leaks the lowest priority. This allows you to focus on the repairs that offer the fastest energy savings for your air system.

Step 3: Report & Repair The Leaks

Carrying out a leak detection survey is pointless if the leaks are not repaired. Following the survey, you will be issued a comprehensive leak detection report. This report details every leak by tag number, precise location, photographic evidence, and its calculated annual energy cost, providing a clear, prioritised action plan. Our team can then carry out all necessary repairs to the highest standard.

Why Regular Air System Monitoring and Inspection Matters

Many businesses view air leakage as a minor nuisance, but in an industrial setting, it is a major financial drain. Regular monitoring and inspection of your air systems are essential for maintaining peak efficiency. Without routine checks, your compressed air system will naturally degrade over time due to loose connections, corroded pipes, and worn seals.

P: Implementing a schedule for professional leak surveys ensures that your system remains tight and efficient. Beyond just saving money on your electricity bill, regular detection prevents the “false demand” that forces your compressors to work harder than necessary. This proactive approach to maintenance not only extends the life of your equipment but also stabilizes system pressure, ensuring your pneumatic tools and production lines operate without interruption.

Our Advanced Ultrasonic Leak Detection Technology

Traditional methods like listening or applying soapy water are slow, unsafe around electronics, and completely ineffective in a noisy industrial environment. Our professional leak detection service uses the latest tools and technology to find leaks without interrupting your operations.

- Ultrasonic Leak Detectors: Our primary tools are industrial ultrasonic leak detectors. These devices are equipped with sensitive microphones that filter out audible factory noise and isolate the high-frequency sound waves from leaks. This allows us to detect and pinpoint leaks quickly and accurately.

- Acoustic Imaging Cameras: For complex air systems, we also utilise advanced acoustic imaging cameras, such as the Fluke ii900 Sonic Industrial Imager. This state-of-the-art detection technology uses an array of microphones to create a visual “sound map,” allowing us to literally see the sound of every leak on a screen in real-time. This helps us locate leaks in seconds, even from a distance.

- Thermal Verification: Where necessary, we can also employ thermal imaging checks to identify overheating in compressor components, ensuring the source of the leak isn’t caused by heat-induced failure or insulation breakdown.

The True Cost of Unaddressed Compressed Air Leakage

Ignoring even the smallest air leakage can have a significant financial and operational impact. The true cost extends far beyond just wasted energy:

- High Energy Consumption: Your compressor has to run for longer and cycle more often to compensate for the constant pressure loss. Since energy accounts for over 70% of a compressor’s lifecycle cost, this is a massive and unnecessary expense.

- Increased Maintenance Costs: This extra runtime accelerates wear and tear on all your equipment, leading to more frequent breakdowns, higher maintenance costs, and a shorter operational lifespan for your compressor.

- Production Downtime & Quality Issues: A drop in air pressure can cause your pneumatic tools and automated systems to underperform. This can lead to production delays, inconsistent product quality, and increased scrap rates.

- Safety Hazards: High-pressure air leaks can be dangerous to personnel, while widespread system degradation increases the risk of a more significant component failure.

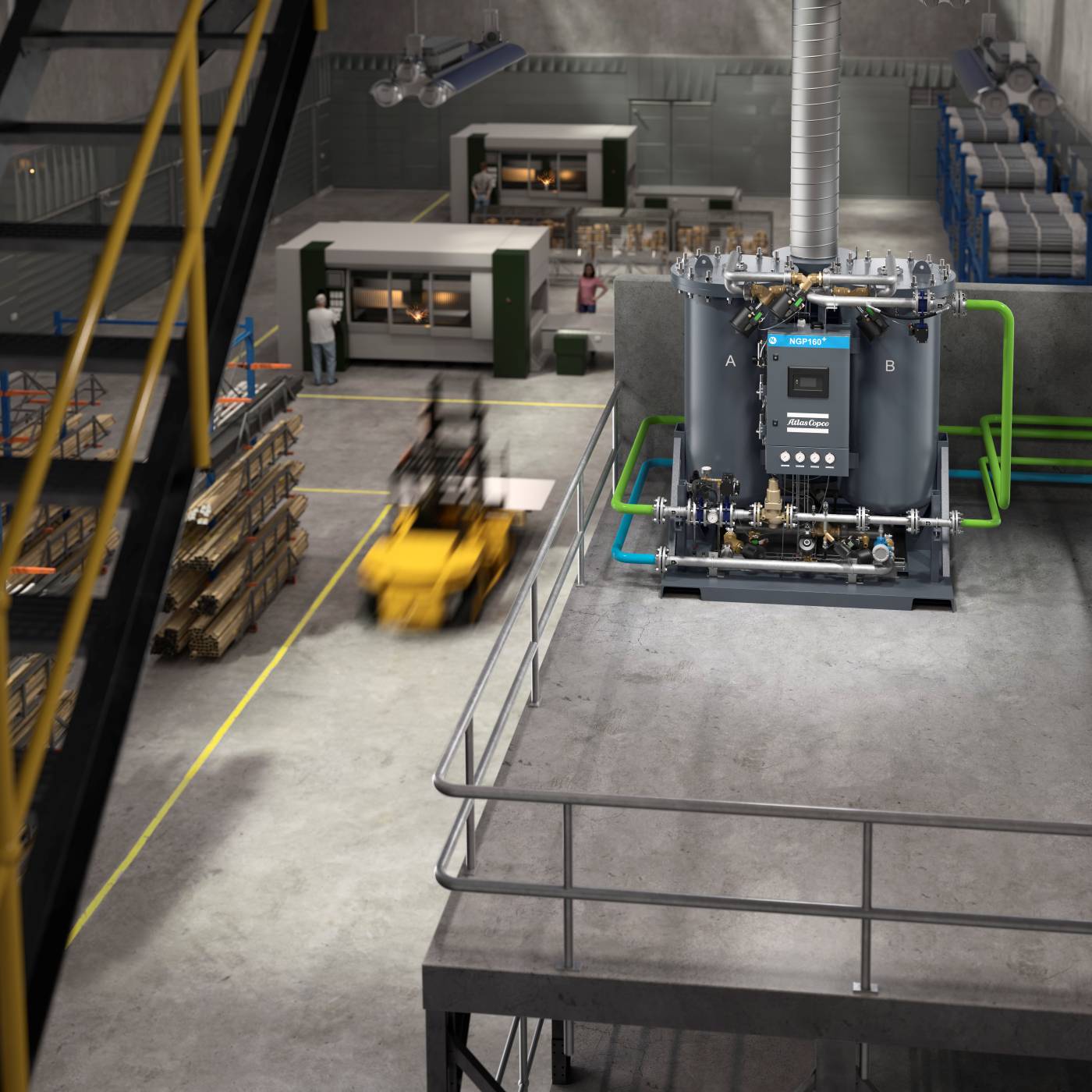

Expert Leak Detection for Atlas Copco & All Major Brands

Our experienced engineers are not just leak detection specialists; we are complete compressed air system auditors. We service and maintain all major compressor brands, with deep, specialist expertise in Atlas Copco systems. This allows us to not only find leaks in your air distribution network but also to diagnose air loss and inefficiencies within the compressor package itself. Whether you run an Atlas, Boge, CompAir, or any other brand, we have the know-how to optimise your entire system.

Frequently Asked Questions about Compressed Air Leak Detection

This varies, but it’s not uncommon for a seemingly well-maintained system to have a leakage rate of 10-20%. A single 3mm leak can cost over £1,000 per year in wasted electricity. Our promise is to find enough annual energy savings to deliver a full return on your investment in under 12 months.

Yes. Our ultrasonic leak detection equipment is specifically designed to work in noisy industrial environments. It filters out audible background noise and isolates the high-frequency acoustic sound of air leaks, so we don’t have to interrupt your production.

While you can listen for hissing sounds during a plant shutdown, the most accurate way to check if a compressor or the wider system is leaking is via an ultrasonic leak audit. If you notice your compressor cycling on and off when there is no production demand, or if it struggles to maintain pressure, you likely have significant air leaks.

The cost of a compressed air audit or leak survey depends on the size of your facility and the complexity of your air system. However, for most industrial sites, the service pays for itself almost immediately through the energy savings identified. Contact us for a bespoke quote tailored to your site requirements.

We provide our compressed air leak detection services across Scotland. Our teams are regularly in Glasgow, Edinburgh, Stirling, Dundee, Aberdeen, and the surrounding areas. Contact us to schedule a survey.

An acoustic imaging camera is an advanced piece of detection equipment that uses dozens of microphones to “see” sound. It overlays a heat map of all sound sources onto a visual image, allowing our engineers to instantly locate leaks and pinpoint the exact location of multiple leakages from a safe distance.